Laminated cardboard and flexo cardboard are two distinct types of cardboard used in packaging and printing, differing in their production processes, structure, and applications. Here’s a detailed breakdown of the differences:

Laminated Cardboard

- Definition and Structure:

- Laminated cardboard is created by bonding multiple layers of paper or cardboard together, often with an adhesive, to form a thicker, more durable material. The "lamination" can also refer to adding a protective layer (like plastic, foil, or a glossy coating) to the surface for enhanced strength or aesthetics.

- It typically consists of a core material (like corrugated cardboard or solid board) with one or more outer layers laminated onto it.

- Production Process:

- The process involves layering sheets of paperboard or other materials and pressing them together under heat or pressure with glue or other bonding agents.

- If a protective film is added (e.g., plastic or varnish), it’s applied using specialized lamination equipment to ensure a smooth, sealed finish.

- Properties:

- Strength: Offers high durability and rigidity due to the layered construction.

- Finish: Often has a smooth, glossy, or matte surface, making it ideal for high-quality printing and branding.

- Moisture Resistance: When laminated with plastic or coatings, it can resist water and humidity better than uncoated cardboard.

- Thickness: Can vary widely depending on the number of layers and materials used.

- Applications:

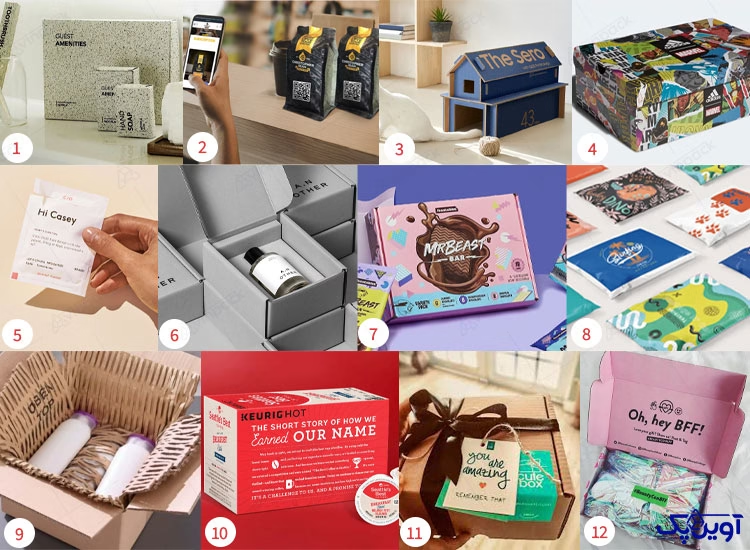

- Commonly used for premium packaging (e.g., cosmetics, electronics, or luxury goods) where appearance and protection are critical.

- Also found in displays, book covers, or products requiring a polished look and added strength.

- Printing:

- Supports high-resolution printing techniques like offset printing, which allows for vibrant colors and fine details.

Flexo Cardboard

- Definition and Structure:

- Flexo cardboard isn’t a specific type of cardboard but rather refers to cardboard (usually corrugated) that has been printed using flexographic (flexo) printing technology. The base material is typically corrugated cardboard, made of a fluted core sandwiched between two linerboards.

- The term "flexo cardboard" often implies the combination of this material and the printing process applied to it.

- Production Process:

- Flexo printing involves pressing a flexible rubber or photopolymer plate with raised designs onto the cardboard surface, transferring ink directly onto it.

- The cardboard itself is produced separately through corrugation (for corrugated flexo cardboard) or as a solid board, then fed into a flexo printing press.

- Properties:

- Strength: Depends on the cardboard type (e.g., single-wall or double-wall corrugated), but it’s generally sturdy and lightweight, ideal for shipping.

- Finish: The surface is rougher compared to laminated carton boxes, and the print quality is typically less refined, with simpler designs and fewer colors.

- Moisture Resistance: Without additional coatings, it’s less resistant to water unless treated separately.

- Flexibility: The corrugated structure makes it more flexible and shock-absorbent than solid laminated boards.

- Applications:

- Widely used for shipping boxes, retail packaging, and point-of-sale displays where cost-efficiency and functionality outweigh aesthetics.

- Common in industries like food and beverage, e-commerce, and logistics.

- Printing:

- Flexo printing is fast and cost-effective, suited for large runs with basic designs (e.g., logos, text, or simple graphics). It’s less precise than offset printing used on laminated boxes.

Key Differences

| Aspect | Laminated Cardboard | Flexo Cardboard |

|---|---|---|

| Structure | Multi-layered with optional protective film | Typically corrugated with printed surface |

| Production | Layering and bonding, often with coatings | Corrugation + flexographic printing |

| Appearance | Smooth, premium finish | Rougher, utilitarian look |

| Print Quality | High-resolution, detailed graphics | Simpler, less detailed printing |

| Strength | Rigid and durable | Strong but more flexible/shock-absorbent |

| Cost | More expensive due to materials/process | Cost-effective for large volumes |

| Applications | Luxury packaging, displays | Shipping boxes, basic packaging |

| Moisture Resistance | Higher (with coatings) | Lower (unless treated) |

Summary

- Laminated cardboard is about enhancing appearance and durability, often with a sleek finish and superior print quality, making it ideal for high-end products.

- Flexo cardboard prioritizes practicality and cost-efficiency, leveraging corrugated material and flexo printing for functional, mass-produced packaging.

If you’re choosing between them, it depends on your needs: laminated for premium branding, flexo for affordable, robust utility. Let me know if you’d like deeper technical details or examples!